Natural Stone Countertop Design | Creating Home's Advanced Custom Aesthetics

With over 13 years of rich experience in stone construction projects, we are dedicated to crafting countertops that blend the elegance of nature with the precision of craftsmanship. Our expertise lies in creating unique and sophisticated designs that transform ordinary spaces into extraordinary living environments.

The Collision Between Nature and Craftsmanship | The Fusion of Countertop and Art

Natural stone is more than just a building material; it is a medium through which we interpret the beauty of nature. Whether it's the sleek lines of a modern kitchen or the timeless elegance of a classic bathroom, our countertops are designed to be the centerpiece of any room.

Stone Interprets the Rhyme of Nature

In the heart of every home, the kitchen stands as a hub of activity and a reflection of personal style. Our natural stone countertops create an artistic soul within this space, blending functionality with aesthetic appeal. Here are some of our signature materials:

- Santorini Quartzite from Brazil: This stunning quartzite features a seamless blend of modern elegance and natural beauty. Its unique patterns and vibrant colors make it an ideal choice for contemporary kitchens, where it can complement a wide range of design themes.

- Babylon Grey Marble from Türkiye: Known for its calming yet sophisticated appearance, Babylon Grey marble adds a touch of refinement to any kitchen island. Its subtle grey tones and intricate veining create a serene and elegant atmosphere, perfect for those who appreciate understated luxury.

- Italian Classic Travertine: This timeless material combines primitive and modern elements, offering a sense of beauty that transcends trends. Its natural variations and earthy tones bring a warm and inviting feel to the kitchen, making it a versatile choice for both traditional and modern settings.

The Secret Realm of Bathroom Wash Basin and Sink

The bathroom is a sanctuary, and our natural stone wash basins and sinks elevate this space to new heights of luxury and comfort:

- Iran Red Travertine Washbasin: The ochre red color of this travertine, combined with its natural holes, creates a luxurious and mysterious ambiance. Each piece is unique, adding a one-of-a-kind touch to your bathroom decor.

- Italian Silver Travertine Countertop: The beige color tone of this travertine perfectly balances the spatial color palette, while its delicate texture and interplay of light and shadow add a sophisticated touch. It is a perfect choice for creating a harmonious and elegant bathroom environment.

- Velvet Red Quartzite: With its warm touch and uniform texture, Velvet Red quartzite adds a subtle sense of luxury to the bathroom. Its rich red hue and smooth surface make it a focal point that enhances the overall aesthetic of the space.

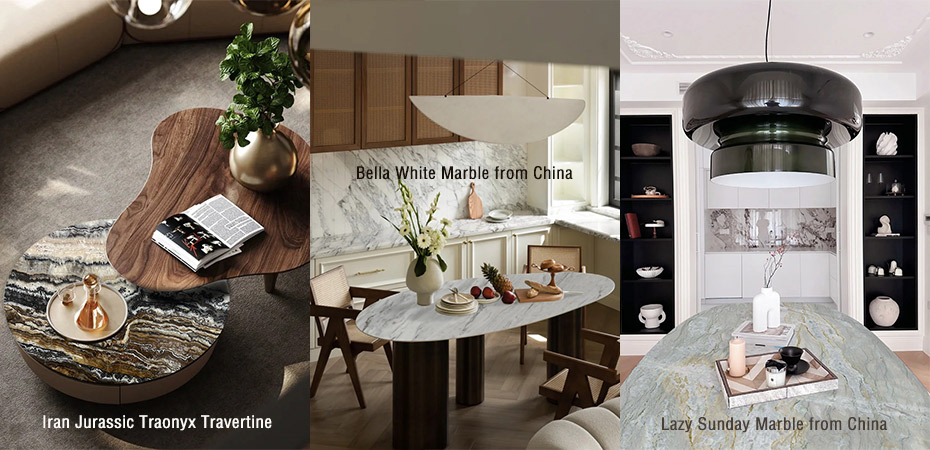

Tabletop and Coffee Table Lifestyle Collection

Beyond their practicality, our natural stone tabletops and coffee tables serve as the finishing touch to home decoration, bringing a sense of elegance and sophistication to any living area:

- Iran Jurassic Traonyx Travertine: The flowing texture and semi-transparent quality of this travertine add a touch of mystery and nobility to coffee tables. Each piece is a unique work of art, enhancing the visual appeal of your living space.

- Bella White Marble from China: Pure white and flawless, Bella White marble features simple and smooth lines that showcase the subtle beauty of Eastern aesthetics. It is a perfect choice for those who appreciate minimalist design and timeless elegance.

- Lazy Sunday Marble from China: The warm tones and natural decorative effect of Lazy Sunday marble create a feeling of harmony and balance. It invites a sense of relaxation and well-being, making it an ideal choice for creating a cozy and inviting living environment.

At STONELINK, we are committed to delivering the highest quality natural stone products that not only meet but exceed your expectations. Our 13 years of experience in the industry have equipped us with the knowledge and skills to create custom solutions that transform your home into a space of beauty and functionality. Whether you are looking to revamp your kitchen, enhance your bathroom, or add a touch of elegance to your living area, we are here to help you achieve your vision.

Contact us today to discover how our natural stone countertops and decor can bring your dream home to life.